Electric Motor Repairs

Electric motor repairs, rewinds and overhauls – 24/7 Emergency Service available

Motor Servicing, Repairs, Rewinding

& Maintenance Specialists

Highly trained engineers

on call 24 hours a day 365 days a year

24 Hour Call Out

Service & Support

AC Motors

CovElec provides a wide range of AC motors for same-day delivery and also offers electric motor repairs within 24 hours. When an AC motor breaks down it inevitably results in unplanned downtime.

CovElec’s aim is to get you back up and running as quickly as possible. The fastest option might be achieved with motor replacement or, depending on the AC motor specification and breakdown fault, motor repair might be the quicker option.

CovElec can collect your AC motor to provide a rapid assessment and will then provide a repair or replacement, usually within 24 hours.

- Fully certified engineers

- Load testing

- Core testing

- Armature testing

- Field testing

- AC motor rewind

- DC motor rewind

- Varnishing stators & rotors

- Shimming & undercutting commutators

- Wash & stove windings

DC Motors

Providing high torque performance at low speed, DC motors are frequently used across applications such as paper and steel mills, as well as coilers, winders and lifting mechanisms. CovElec is able to support your application by providing new replacement DC motors, as well as providing a rapid DC motor repair service.

As DC motor applications are often integral to operational productivity, it can be critical to minimise the downtime. Depending on the specification of your DC motor, the faster option to get your application back up and running might be repair rather than replace.

CovElec will collect your DC motor to provide a rapid assessment and will then support a repair or replacement.

Servo Motors

Speed of repair is key

With servo motors typically used in precision manufacturing, down time means high cost. If a servo motor develops a fault, it’s vital that a repair is made as rapidly as possible. A fast return to service must be combined with a guarantee of a highly proficient repair that provides lasting, high performance motion control.

From printing and packaging to electronic device production, servo motors are a crucial component for manufacturing processes. Downtime means cost through reduced production, the potential of missed deadlines and reputational damage. For these reasons, if a servo motor develops a fault, it’s imperative that it’s repaired and recommissioned as soon as possible. A servo motor is capable of exacting precision at high speed, so it’s vital that any repair returns it to the same performance levels as when specified from new.

Geared Motors

CovElec hold an extensive range of geared motors and through our distribution partnerships have access to a large portfolio of products.

Alongside our team’s experience in geared motor solutions and our 24/7 service we are able to respond to urgent requirements to ensure minimum downtime.

We are able to supply and service geared motors from some of the biggest names in the industry including Lenze, Motovario, Bonfigolioli, Leroy Somer, Nord & many more.

- Right Angle Geared Motors

- Inline Helical Geared Motor

- Helical Bevel Geared Motor

- Parallel Shaft Mounted Geared Motor

- Mechanical Variable Speed

- Shaft Mounted Speed Reducers

CovElec offer extensive repair and refurbishment services backed up by cutting edge test facilities. We have a team of experienced and skilled engineers who are on hand to identify the most economic and expedient solution for our customers whether this be by sourcing a replacement or by repairing and refurbishing the existing geared motor.

Our clients range from Water Authorities, Food & Beverage Manufacturers, Quarries, Manufacturing, Universities, Facilities Management, Industrial, and Domestic Customers.

Electrical Repairs

Repairing an electric motor is often the only solution where replacement motors are not available or where the faulty motor is of a specialist design or type.

CovElec offer a full rewind service for all AC and DC motors, new bearings are fitted, armatures can be skimmed and undercut, field coils and interpoles can be re-leaded and brush gear renewed, therefore ensuring many more years of reliable service.

Additionally CovElec’s specialist engineers are able to test electronic control systems, diagnose faults and effect repairs as required.

Electrical Service Includes:

- Fully certified engineers

- Load testing

- Core testing

- Armature testing

- Field testing

- AC motor rewind

- DC motor rewind

- Varnishing stators & rotors

- Shimming & undercutting commutators

- Wash & stove windings

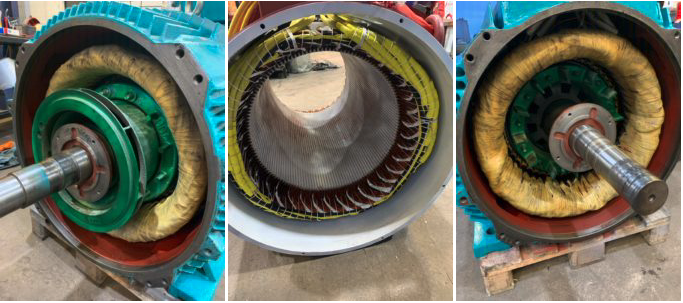

Extensive Rewind Service in both AC & DC style motors

All the skills and engineering knowledge remains in place and motor repairs and rewinds are still key to our success. So, from a small AC/DC motor, to a servo or stepper motor, through to large generators, we’ve experience throughout the range.

Motor rewinds allow operators to avoid the time or cost disadvantages associated with sourcing a new motor. During breakdown situations, CovElec provides its customers with a reactive maintenance support framework. In many cases, motors can be back on-site and running within 24 hours of the initial failure. CovElec can also ensure that motors operating in redundancy can be rewound as part of a structured maintenance plan to minimise downtime.

CovElec employs a team of in-house motor rewind experts. Offering extensive experience in the art of rewinds, this team of specialists can carry out work of exceptional quality within reduced timeframes. With this experience and state-of-the-art winding machines, CovElec can complete an average rewind within 8-10 hours. Motors of almost any age and configuration can be serviced by the rewinds team.

- AC & DC motor rewinds

- 24 hr turnaround

- Motors from 1 kW up to 1000 kW

- Almost any age or configuration

- Dedicated team & workshop

- Breakdown response

- Core loss testing

- Noise & vibration testing

Quality at the Core

Quality is at the forefront of all rewinds. Core loss testing is available in-house to prove the performance of rewound motors, while specialists assess noise and vibrations to ensure assets are ready to re-enter service.

CovElec has a proven track record carrying out quality rewinds for businesses in the industrial, commercial, water, food & beverage sectors. This means that CovElec has the experience to deliver motor rewinds quickly, while never sacrificing quality.